|

3start |

|

3fahrt |

|

A journey to the Moosbach-Rheinheimer-Railway |

|

3fahrt - Dream and fiction in 1:87 |

|

3fahrt |

|

A journey to the Moosbach-Rheinheimer-Railway |

|

Equipment of Moosbach-Rheinheimer Railway |

|

Trix and Trix-Express are trade marks and registered trade marks of Trix Modelleisenbahn GmbH & Co. KG, Göppingen/Germany. Trade marks or product names mentioned are trade marks or registered trade marks of the respective owners. |

|

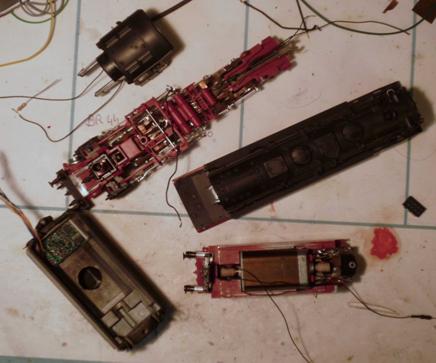

For this conversion to the Trix Express System I used a older Class 44 Model from Roco

Facts:

· BR 44 of Deutsche Reichsbahn (DR) · Roco 43263 · LOA: 257 mm · Weight 642 g · 4 traction tires · Roco engine, tender drive · LED lights (self build) · Lenz DCC Decoder Standard+ in the tender · Seuthe #10 steam generator · Weathering

|

|

BR 44 Roco Engine Class BR 44 for Trix-Express |

|

All pictures from 2010 © H. Fengel |

|

See the Movie: Class 44 of the Moosbach-Rheinheimer Eisenbahn |

|

Technology: The conversion to the Trix Express System was done with additional steel tyres from Ton Jongen for the first and last driving wheel pivots (4 x EL 1114 00 steel tyres ø19,5), and for the first and last pivots of the tender (4 x EL 1122 00 steel tyres ø15,5). The work included some cutting on the die-cast tender frame to make room for the extra steel tyres. The wheels of the first axles where converted to Trix Express with a proper washer.

DCC operation:

For the DCC conversion I choose the Lenz DCC Decoder Standard+. This decoder has enough power on the Aux ports of 300 mA for the Seuthe #10, which smokes better then the digital version with less amperes. The decoder fits in the tender body without any changes, only the engine contact poles must be shortened by 4 mm. The electrical connection between tender and loco was done by decoder wires. The decoder was connected according to the manual and needs no chances in the CVs (beside the engine address CV3) The functions cabin light and steamer are assigned to F1, the light for the chassis and engine (self constructed) is connected to the rear lights. As the engine is normally not backwards on the tracks, this is ok. |

|

Technology: |

|

Beside the necessary changes for the Trix-Express System, i wanted to enhance the Roco BR 44 157 with a DCC decoder and weathering. The engine (43263) was purchased for 70 Euro „out of the bay“ and has despite the age good running behavior. |

|

Chassis lights: This engine should be the first locomotive of the Moosbach-Rheinheimer Railways to get a suspension lighting. The 5 warm-white 0603 SMD LEDs were glued with super glue directly under the round (see picture) and connected in series with wire-wrap technology to locomotive ground. LEDs and wires are fixed with super glue. A resistor of 1 kOhm in series provides the appropriate illumination. For such soldering work, you should have a very steady hand, eyes like a hawk and a proper soldering iron equipment. If you miss experience in soldering SMD components, conductive ink can be an alternative. |

|

Weathering: Today's museum locomotives are well maintained, so I've adapted the operation traces of a engine, which is in serious train service in epoch IIIa. For this I have done „weathering" gently with powder paints and varnishes. The wheels were repainted to match the unrealistic visible silver wheels and axle ends. With traces of oil in "drybrush" technology I highlighted wheels, brakes and other chassis parts with brown and black paint. With bright powder colours and a soft brush I added traces of lime by the water and highlighted the boiler pipes. Interesting is, that even well kept museums engines never have a black homogeneous surface. Subtle traces of rust on the boiler and circulation and bright dust on skirting and chassis with powder colours creates the impression of a much-used engine and take the plastic shining of the surface. |

|

Cab lighting: A single warm-white 0603 SMD LED was glued with super glue in the cab roof and connected with copper wire to a 1 kohm resistor. The detailing of the rear wall of the boiler was highlighted with white, red and copper-colored paint pens.

Seuthe steam generator: In the locomotive I installed a Seuthe No. 10 steam generator. This "analog" steam generator produces significantly more steam than the digital counterparts, but needs a DCC decoder with enough power on the aux ports. Important to me is the fact, that under DCC the steamer can be disabled and therefore will not be operated without distillate on long runs. The hull of the steam generator is connected to locomotive ground and to the DCC decoder function output so it is operated with half-wave AC |

|

Real coal on the tender: The bad imitation of coal by plastic on the tender was filled with a layer of inexpensive "real coal" from a used water filter cartridge. The coal is having the right size and is glued with a water-white glue mixture (50/50), do not forget a small drop of dishwasher |